Omni Heat Exchangers

With the largest selection of UL and CUL listed waste oil heaters in the industry, there's an Omni that can meet your heating needs. Why settle? Experience the difference.

Omni OWH-75

BTU's/HR Input - 75,000

BTU'S/HR OUTPUT - 60,000

GALLONS PER HOUR - 0.5

VOLTAGE REQUIREMENTS 115

AMPS FULL LOAD w/PUMP - 10.5

FAN MOTOR HP - 1/10

FAN RPM - 1625

FAN DIA/PITCH - 14/23

CFM (FREE AIR) N/A

CFM W/DUCTWORK @ 100FT - N/A

EFFECTIVE AIR FLOW - 50ft

FLUE SIZE - 6"

WEIGHT W/BURNER - 155lbs

SHIPPING WEIGHT - 190lbs

DIMENSIONS L/H/W in - 47.5/22/28

SHIPPING DIMENSIONS L/H/W in - 48/22.5/28

BTU's/HR Input - 150,000

BTU'S/HR OUTPUT - 120,000

GALLONS PER HOUR - 1.0

VOLTAGE REQUIREMENTS - 115

AMPS FULL LOAD w/PUMP - 14.6

FAN MOTOR HP - 1/4

FAN RPM - 1075

FAN DIA/PITCH - 18/36

CFM (FREE AIR) - 3762

CFM W/DUCTWORK @ 100FT - 1,380

EFFECTIVE AIR FLOW - 60ft

FLUE SIZE - 8"

WEIGHT W/BURNER - 240lbs

SHIPPING WEIGHT - 375lbs

DIMENSIONS L/H/W in - 42/22/25.5

SHIPPING DIMENSIONS L/H/W in - 64.5/30/49

BTU's/HR Input - 250,000

BTU'S/HR OUTPUT - 215,000

GALLONS PER HOUR - 1.75

VOLTAGE REQUIREMENTS - 115

AMPS FULL LOAD w/PUMP - 15.6

FAN MOTOR HP - 1/3

FAN RPM - 1075

FAN DIA/PITCH - 24/18

CFM (FREE AIR) - 4466

CFM W/DUCTWORK @ 100FT - 2000

EFFECTIVE AIR FLOW - 70ft

FLUE SIZE - 8"

WEIGHT W/BURNER - 365lbs

SHIPPING WEIGHT - 535lbs

DIMENSIONS L/H/W in - 44/30/28.5

SHIPPING DIMENSIONS L/H/W in - 64.5/39/49

BTU's/HR Input - 350,000

BTU'S/HR OUTPUT - 300,000

GALLONS PER HOUR - 2.4

VOLTAGE REQUIREMENTS - 115

AMPS FULL LOAD w/PUMP - 18.7

FAN MOTOR HP - X2 @ 1/4 ea

FAN RPM - 1075

FAN DIA/PITCH - 18/36

CFM (FREE AIR) - 6275

CFM W/DUCTWORK @ 100FT - 1600

EFFECTIVE AIR FLOW - 80ft

FLUE SIZE - 8"

WEIGHT W/BURNER - 400lbs

SHIPPING WEIGHT - 575lbs

DIMENSIONS L/H/W in - 54/29.5/28.5

SHIPPING DIMENSIONS L/H/W in - 76/38/49

BTU's/HR Input - 350,000

BTU'S/HR OUTPUT - 300,000

GALLONS PER HOUR - 2.4

VOLTAGE REQUIREMENTS - 115

AMPS FULL LOAD w/PUMP - 18.7

FAN MOTOR HP - X2 @ 1/4 ea

FAN RPM - 1075

FAN DIA/PITCH - 18/36

CFM (FREE AIR) - 2X 3762

CFM W/DUCTWORK @ 100FT - 1600

EFFECTIVE AIR FLOW - 100ft

FLUE SIZE - 8"

WEIGHT W/BURNER - 425lbs

SHIPPING WEIGHT - 600lbs

DIMENSIONS L/H/W in - 54/29.5/28.5

SHIPPING DIMENSIONS L/H/W in - 76/38/49

BTU's/HR Input - 500,000

BTU'S/HR OUTPUT - 410,000

GALLONS PER HOUR - 3.4

VOLTAGE REQUIREMENTS - 115

AMPS FULL LOAD w/PUMP - 20.7

FAN MOTOR HP - X2 @ 1/3 ea

FAN RPM - 1075

FAN DIA/PITCH - 24/18

CFM (FREE AIR) - 9001

CFM W/DUCTWORK @ 100FT - 3701

EFFECTIVE AIR FLOW - 100ft

FLUE SIZE - 8"

WEIGHT W/BURNER - 660lbs

SHIPPING WEIGHT - 725lbs

DIMENSIONS L/H/W in - 72/38/34.5

SHIPPING DIMENSIONS L/H/W in - 92/44/50

BTU's/HR Input - 500,000

BTU'S/HR OUTPUT - 410,000

GALLONS PER HOUR - 3.4

VOLTAGE REQUIREMENTS - 115

AMPS FULL LOAD w/PUMP - 20.7

FAN MOTOR HP - X2 @ 1/3 ea

FAN RPM - 1075

FAN DIA/PITCH - 24/18

CFM (FREE AIR) - 2X 4500

CFM W/DUCTWORK @ 100FT - 3701

EFFECTIVE AIR FLOW - 120ft

FLUE SIZE - 8"

WEIGHT W/BURNER - 685lbs

SHIPPING WEIGHT - 750lbs

DIMENSIONS L/H/W in - 72/38/34.5

SHIPPING DIMENSIONS L/H/W in - 92/44/50

BTU's/HR Input - 75,000 - 500,000

BTU'S/HR OUTPUT N/A

GALLONS PER HOUR - 0.5 - 3.5

VOLTAGE REQUIREMENTS - 115

AMPS FULL LOAD w/PUMP - N/A

FAN MOTOR HP - N/A

FAN RPM - N/A

FAN DIA/PITCH - N/A

CFM (FREE AIR) - N/A

CFM W/DUCTWORK N/A

EFFECTIVE AIR FLOW - N/A

FLUE SIZE - 6" - 10"

WEIGHT BURNER - 42lbs

WEIGHT PUMP - 25lbs

DIMENSIONS L/H/W in - N/A

SHIPPING DIMENSIONS L/H/W in - N/A

Every OMNI waste oil heater is built with high grade stainless steel heat exchangers and is backed with a with a 10 year warranty to match. From the Floating Crimped Heater Exchangers, to the Patented Flame Control System, our waste oil heaters will provide you with long lasting ROI.

Our Flame Control System cuts out much of the time consuming and costly maintenance incurred with many other waste oil heaters. By precisely controlling the temperature of the waste oil before ignition, the OMNI will not only burn much more consistently, but is completely free of carbon build up which clogs the block. For the small amount of heater maintenance needed, we would rather make it easy for you to clean yourself than be charged for costly service calls.

With tuned axial fans and the large vent area design, OMNI Waste Oil Heaters have the highest warm air output, most CFM's and quickest recovery times in the industry. This means less waste oil burnt, less run-time, less electricity used, and less wear and tear on the equipment for an overall better experience.

Centrally locate the heater in longer building applications to provide better heat distribution by throwing heat in two directions. Available in the OWH-350 and OWH-500 models only.

OMNI is the only waste oil burner manufacturer who will guarantee the oil preheater block will not carbon the oil internally. Therefore, the industry normal of removing the carbon in the preheater block is not necessary. This design ensures that OMNI customers will never need to remove the burner for periodic carbon cleaning!

Omni Heater Benefits:

• Non-carboning oil heater block / Industry normal cleaning not required

• Most thorough burn greatly reducing ash deposits

• Less stress on metals preventing over fire after initial flame adjustment / No target burn-out

• Clean heater once a season under normal conditions

• The most reliable and consistent operation

• Greatest efficiency

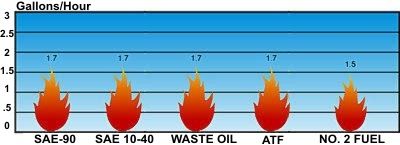

• Only system that burns 90 weight oils

The OMNI Flame Control System is a patented system that consists of an Oil Flow Supply Pump and a Non-Carboning Oil Preheater that controls the fuel by volume. No Adjustments needed for various viscosities. The Flame Control System comes standard with all OMNI equipment. This system can also be purchased separately with a universal burner mounting flange allowing easy retrofitting of our burner system to various configurations and sizes of combustion chambers. Initial flame adjustment is all that is needed with complete control thereafter.

Variably Controlled Waste Oil Pump. This Remote flow control pump supplies the exact gallons of oil per hour to each waste oil burning appliance, regardless of viscosity. This pump is to be located at the oil supply tank and is capable of pushing 100' to the used oil firing unit. Unique ability to adjust for every application unique to customer.

There are many who have easy access to their oil preheater block, but cleaning the hard lava-like carbon is not an easy task. Others request the entire burner be serviced at least annually. Part of that service is flushing their oil preheater block of carbon buildup. Some must do this more than others, as frequently as twice a season. Fully cleaning and removing carbon is a difficult chore. Even after cleaning, carbon chunk particles can remain. Shortly after service, they can plug the oil nozzle, shutting the unit down. This causes a lot of down time and repeat service, not experienced with OMNI units.

Additionally, some manufacturers request their customers shut the unit down during the summer months to eliminate the carboning process. This is not necessary with the OMNI system. Just leave your unit on and it will automatically start by the thermostat when heat is needed. OMNI burners do no need to be torn apart to access the heater block for cleaning. These are a few of the operating procedures COMPETITORS believes are standard; NOT WITH OMNI!

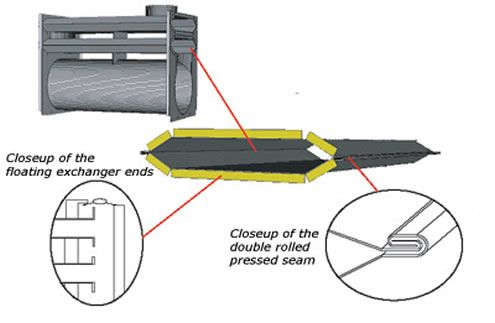

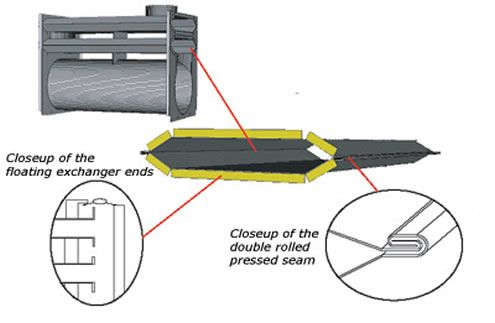

Omni Heat Exchangers consist of formed 304L 16 Ga. Stainless steel plates that have a double rolled pressed seam. This pressed seam construction eliminates the possibility of stress cracks that can occur from welding. Stainless steel is the longest lasting, most durable material available for higher temperature applications. Other manufacturers use lower cost materials and try to compensate with thicker walls of inferior steel.

Omni's long combustion chamber burn path and oil flow control capabilities eliminate the need for a target wall avoiding direct exposure to flame and extreme temperature changes which destroy the target and require other inferior designs to be replaced frequently.

Combined with a Solid State Circuit Board Controller, these items precisely control the oil and air temperatures to insure stable viscosity for optimum control of the flame resulting in a thorough burn. Industry normal annual parts kit not needed with the OMNI system! Re-adjustment of electrodes and nozzle replacement every 5 years is all that is needed due to erosion only. OIL HEATER BLOCK WILL NOT BUILD UP CARBON INSIDE ITS OIL PASSAGES!

Omni includes a built-in vane oil-less compressor as standard equipment and requires no maintenance which allows the unit to be operated 24 hours/day without an external air supply.

Our oil flow control supply pump with a variable speed motor supplies the exact gallons perhour to the heater regardless of variations in fuel viscosity. No need for constant adjustment. Capable of pushing 100+ feet.

Up to 90% efficient, Omni Waste Oil Heaters produce more heat for every gallon of waste oil. Burns clean with zero smoke, when U.L. tested the equipment the emissions were between 0-1 on a Bacharach scale of 0-10, cleaner burning than some standard oil burners

Omni waste oil heaters have incorporated a unique method of throwing air across their combustion chamber with high volume pressure style fans. This type fan is used in lieu of typical free air fans for area heating or squirrel cage blowers for ducting heat to various rooms. As a result, installation is easier, electrical costs are minimized, and shipping costs are reduced.

Swing out burner doors mean no fuel or air lines to disconnect. Removal of two nuts and electrical safety plug allows easy access to flame end cone and nozzle for quick service. Combustion chamber's plates open at both ends for full pass through easy access cleaning.

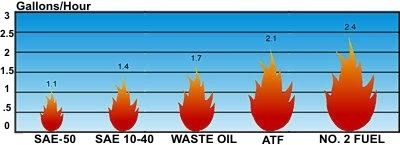

These charts demonstrate the efficiency & consistency of the Omni Waste Oil Flame Control System

Omni Heat Exchangers

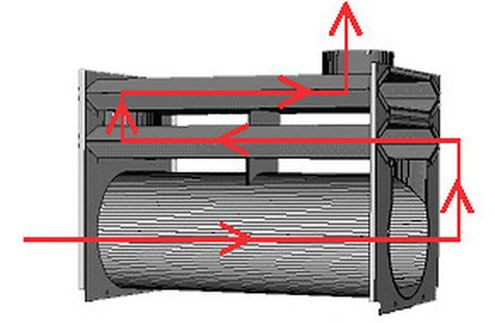

3 Pass Design

Consistent Burn

Dual Clean Out Doors

Pass Through Cleaning

High Volume Fans

© 2018 All rights reserved.